MEASURING EXTENSION

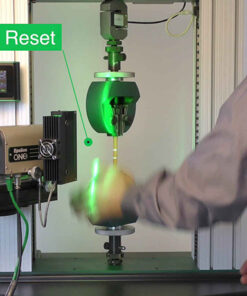

Preparation of the test specimen is quick and easy. A punch is supplied to cut narrow strips of adhesive reflective tape. The gage length is defined by attaching these two reflective strips to the sample. Any gage length can be used and this is accurately measured by the laser at the start of the test.

When force is applied to the sample, the laser scanning beam will measure the separation of the reflective gage marks at a scan rate of 320 scans per second.

Unlike other non-contacting extensometers, if the scanning beam is interrupted for any reason, elongation measurements will automatically be corrected when normal operation is resumed.

VI

VI