Demand for high-performance, energy-efficient electronics is driving the development of advanced devices with ever smaller, more densely packed features and complex 3D structures. Ramping production of these cutting-edge microprocessors, memory devices, and other products is extremely challenging and requires high-resolution, atomic-scale analysis of features buried deep within the device. Transmission electron microscopy (TEM) is increasingly becoming the go-to technique for this kind of analysis and relies on high-quality samples produced with focused ion beam (FIB) milling.

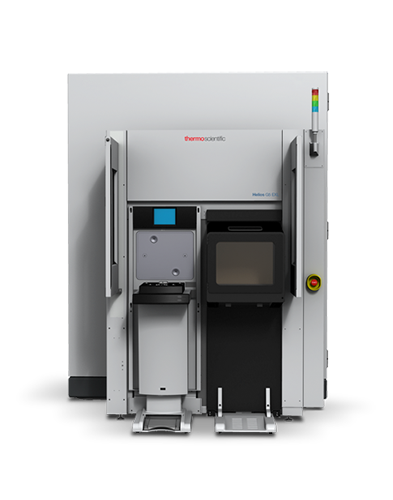

The Thermo Scientific Helios 5 EXL DualBeamis a 300mm full-wafer focused ion beam scanning electron microscope (FIB-SEM), designed to address TEM sample preparation challenges in the semiconductor industry. The Helios 5 EXL DualBeam is capable of preparing samples for today’s most advanced process nodes, including sub-5nm and gate-all-around technology.

Maximizing sample throughput and productivity

Utilizing advanced machine learning and closed-loop end pointing, the Helios 5 EXL DualBeam delivers enhanced cut placement precision and enables you to consistently extract high-quality lamella from your most challenging samples.

Advanced machine-learning automation capabilities make ultra-thin TEM sample generation routine and consistent, providing unparalleled, sub-nanometer insight into more interfaces, films, and profiles to measure at sub-nanometer resolution. The Helios 5 EXL DualBeam ensures efficient and consistent TEM sample preparation workflows by combining wafer and defect navigation with recipe definition and execution in a single, fully integrated program. This automation supports a higher tool-to-operator ratio, maximizing sample throughput and technical resource productivity.

| Thermo Scientific Phoenix Ion Column |

- Gallium focused ion beam

- Up to 65 nA maximum beam current

- Low-voltage (500 V) performance for high sample preparation quality

- Ion beam resolution at coincident point and 30 kV: 4.0 nm using preferred statistical method

- Ion source lifetime: 1,000 hours guaranteed

|

| Thermo Scientific Elstar Electron Column |

- An ultra-high-resolution immersion-lens field-emission SEM (FESEM) column

- The ultra-stable Schottky field emitter gun features UC+ monochromator technology

- Electron beam resolution:

- 1.0 nm @ 15 kV

- 0.9 nm @ 1 kV

- Electron source lifetime: 12 months

|

| Gas delivery |

- Thermo Scientific MultiChem Gas Delivery System

- Slots for up to 6 individual chemistries

- Single gas injection system

- Port for up to 3 independent GIS units

|

| Detectors |

- Elstar in-lens SE detector (TLD-SE)

- Elstar in-lens BSE detector (TLD-BSE)

- High-performance ion conversion and electron (ICE) detector for secondary ions (SI) and electrons (SE)

|

| Sample handling |

- Automated handling of 300 mm FOUP with EFEM (GEM300 compliant)

- Manual loading of 300 mm, 200 mm, and 150 mm wafers

|

| Additional options |

- Optical microscope with 920 µm field of view

- 30 kV STEM detector with BF/DF/HAADF segments

- Oxford EDS

- CAD Navigation Compatibility (NEXS and Synopsys Camelot)

- Thermo Scientific iFast Software Semiconductor Wafer Navigation (optional)

- Integrated defect navigation based on KLARF 1.2 and 1.8 standards

- User-defined wafer maps and site plans

|

Automated TEM sample preparation software

Thermo Scientific AutoTEM 5 Software combines wafer and defect navigation with recipe definition and execution in a single, fully integrated program, ensuring efficiency and consistency among operators with varying levels of expertise. AutoTEM Software simplifies TEM sample preparation, allowing users to easily schedule multi-site jobs for inverted, plan-view, and top-down TEM sample preparation workflows.

Repeatable, automated deposition and etch

Developed specifically to support automated TEM preparation, the Thermo Scientific MultiChem Gas Delivery System provides highly consistent deposition and etching capabilities and can be utilized with automated applications. The motorized injection needle with saved position presets can be accurately positioned for optimized, reproducible gas delivery to the sample surface. The MultiChem Gas Delivery System is also engineered for serviceability, maximizing tool uptime.

Precision FIB milling for advanced sample preparation

The Helios 5 EXL DualBeam includes the Thermo Scientific Phoenix Ion Column, which provides revolutionary low-kV performance and leading-edge TEM sample preparation.

Automated alignments, high resolution, and consistent results

The high-performance Thermo Scientific Elstar Electron Column features our unique UC monochromatic technology, offering improved resolution and TEM sample end-pointing. New SEM auto-alignments ensure consistent results across multiple tools and operators.

Automated sample manipulation and lift out

With an intuitive method for lift-out and transfer of TEM samples to a grid, the Thermo Scientific EasyLift Nanomanipulator offers low-drift, high-precision movements for simple and consistent creation of traditional or ultra-thin TEM lamella. Highly accurate, easy-to-use, and fast motorized rotation makes the EasyLift Nanomanipulator ideally suited for high-speed inverted or plan-view sample preparation.

Fab-compatible Automated FOUP Loader (AFL) option

The optional Automated FOUP Loader (AFL) enables the Helios 5 EXL DualBeam to be located inside the semiconductor wafer fab. By being closer to the wafer process line (near-line), it can deliver critical information up to three times faster than laboratory-based analysis of cleaved wafer pieces, accelerating the development of new processes and the yield ramp to high-volume production.

Semiconductor Advanced Packaging

Performance, power efficiency, area, and cost are driving packaging innovations. Learn how workflows provide fast, precise, and accurate time-to-data.

Semiconductor research and development

The increasing complexity of semiconductor device structures, along with the shrinking of structural dimensions, means that designing next-generation devices is more challenging and time-consuming than ever before. This, coupled with the fact that the number of technology and design options available is increasing, means a lower probability that any particular design will be commercially successful. As a result, device manufacturers need reliable tools for pathfinding that reduce the number of viable options available and help them implement solutions faster.

Semiconductor metrology

Thermo Fisher Scientific offers a suite of next-generation products with advanced analytical capabilities for semiconductor metrology and inspection. These solutions are designed to help increase productivity in semiconductor fabrication labs by improving quality control and yield in the manufacture of logic, 3D NAND, DRAM, analog, power and display devices.

Semiconductor Failure Analysis

Advanced analytical tools are essential for the detection of any electrical defects that can negatively influence yield, reliability, or performance. With the right equipment, the time and cost associated with electrical fault isolation can be reduced by quickly extracting comprehensive defect data from the sample.

Semiconductor materials characterization

Advanced characterization of these devices can help you deliver on necessary performance, predict and control structural, physical, and chemical properties, as well as correlate your characterization data to parametric test results.

TEM Imaging and Analysis

Thermo Scientific transmission electron microscopes offer high-resolution imaging and analysis of semiconductor devices, enabling manufacturers to calibrate toolsets, diagnose failure mechanisms, and optimize overall process yields.

TEM Metrology

Advanced and automated TEM metrology routines deliver significantly greater precision than manual methods. This allows users to generate large amounts of statistically relevant data, with sub-angstrom-level specificity, that is free of operator bias.

TEM Sample Prep

Thermo Scientific DualBeam systems provide accurate TEM sample preparation for atomic-scale analysis of semiconductor devices. Automation and advanced machine learning technologies produce high-quality samples, at the correct location, and a low cost per sample.

VI

VI