Tinius Olsen supplies the Rockwell Hardness Tester Model FH 30 which is a fully automated, load cell, closed loop, force feedback, force testing system with Rockwell, SuperficialRockwell & Brinell scales (optional) as part of its hardness testing capabilities.

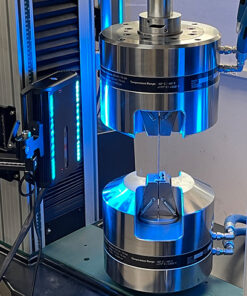

Rockwell hardness testing is a test method based on the measurement of the depth of an indentation forced by a primary (large) load beyond the depth due to a previously applied initial (small) load.

Characteristic

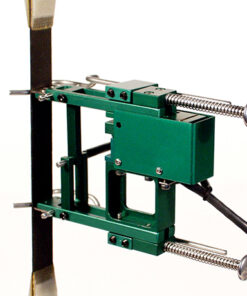

The model FH30 is a new generation of hardness testing instrument with protruding nose design. The long nose design makes it possible to reach as far as 150mm inside a bore or just on flat material similar to any other Rockwell hardness tester.

- Twin-scale Rockwell machine that also provides Brinell testing

- Easy to use, excellent workpiece overview

- Test forces range from 1-187.5kgf, which means that even this basic model is equipped with Rockwell, Superficial Rockwell and Brinell load settings

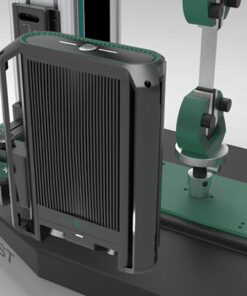

- System control is managed via a simple-to-use 6.5in full color industrial touchscreen that will also display results and statistics

Features

- Load cell, closed loop, force feedback system

- Load range 1-250kgf (9.8-2452N)

- Meets or exceeds ISO, ASTM and JIS standards

- 150mm protruding nose, 200mm throat depth(30-5)

- Force(load) measurement at the indenter position

- 250mm workpiece height (30-5)

- Power LED light near indenter for bright sample illumination

- Removable workpiece clamp, with interchangeable inserts, clamps/holds sample firmly in position (optional)

- Industrial 6.5in touch screen

- USB connectivity

- ABS cover included, protecting machine base against falling objects

- Optional Brinell microscope package for Brinell measurement

Models details:

FH-030-0004:

- 3-150kgf – Rockwell, Superficial Rockwell

- 1-250kgf – Brinell (optional)

FH-030-0005:

- 3-150kgf – Rockwell, Superficial Rockwell

- 1-187.5kgf – Brinell (optional)

Tinius Olsen supplies the Rockwell FH 31 hardness tester which is a fully automated, load cell, closed loop, force feedback, force testing system with Rockwell, Superficial Rockwell & Brinell scales (optional) as part of the hardness testing capability.

Characteristic

The model FH 31-3 is a new generation of hardness testing instrument with protruding nose design. This long nose design allows you to reach as far as 150mm inside a bore or just on flat material similar to any other Rockwell hardness tester. It has working height of 400mm and throat depth of 200mm and can also be optionally equipped with an automatic spindle. Simply push START and the full process of lifting, clamping and testing takes place without operator interference.

- Twin-scale Rockwell machine that also provides the option for Brinell testing

- Easy to use, excellent workpiece overview

- Test forces range from 1-187.5kgf, which means that even this basic model is equipped with Rockwell, Superficial Rockwell and Brinell load settings

- System control is managed via a simple-to-use 8.5in full color industrial touchscreen that will also display results and statistics

Features

- Load cell, closed loop, force feedback system

- Load range 1-250kgf (9.8-2452N)

- Meets or exceeds ISO, ASTM and JIS standards

- 150mm protruding nose, 200mm throat depth(30-5)

- Force(load) measurement at the indenter position

- 250mm workpiece height (30-5)

- Power LED light near indenter for bright sample illumination

- Removable workpiece clamp, with interchangeable inserts, clamps/holds sample firmly in position (optional)

- Industrial 6.5in touch screen

- USB connectivity

- ABS cover included, protecting machine base against falling objects

- Optional Brinell microscope package for Brinell measurement

Models details:

FH-031-0002:

- 3-150kgf – Rockwell, Superficial Rockwell

- 1-250kgf – Brinell (optional)

FH-031-0003:

- 3-150kgf – Rockwell, Superficial Rockwell

- 1-187.5kgf – Brinell (optional)

VI

VI